Want to know more about Sharon Experts’ wig construction? Here is how we build your perfect unit.

About Us

At Sharon Experts, every wig is constructed using professional high-needle techniques developed within Asian production factory environments.

Our work reflects hands-on factory training where precision, structural correctness, and disciplined construction are required for consistent results.

We specialize in accurate wig structure and custom head-fit manufacturing rather than general-size retail production, ensuring each unit is built with purpose, balance, and long-term wearability.

Wigs are not assembled casually. They are constructed using disciplined high-needle methods developed inside professional production environments. Every piece is built for structure, balance, and long-term wear, not just appearance.

We serve clients who want correct construction, custom fit, or reliable batch production. We focus on correct construction, not shortcuts.

Our Construction Standard

Every wig is built using controlled techniques refined through professional production environments.

Our process includes:

• Structured row placement for proper ventilation and balance

• High-needle stitching for long-term durability

• Measured density distribution, not random fullness

• Cap shaping designed to sit naturally on the head

• Consistent methods that ensure repeatable quality

This approach allows each unit to perform reliably beyond the first wear.

Internal Construction Process

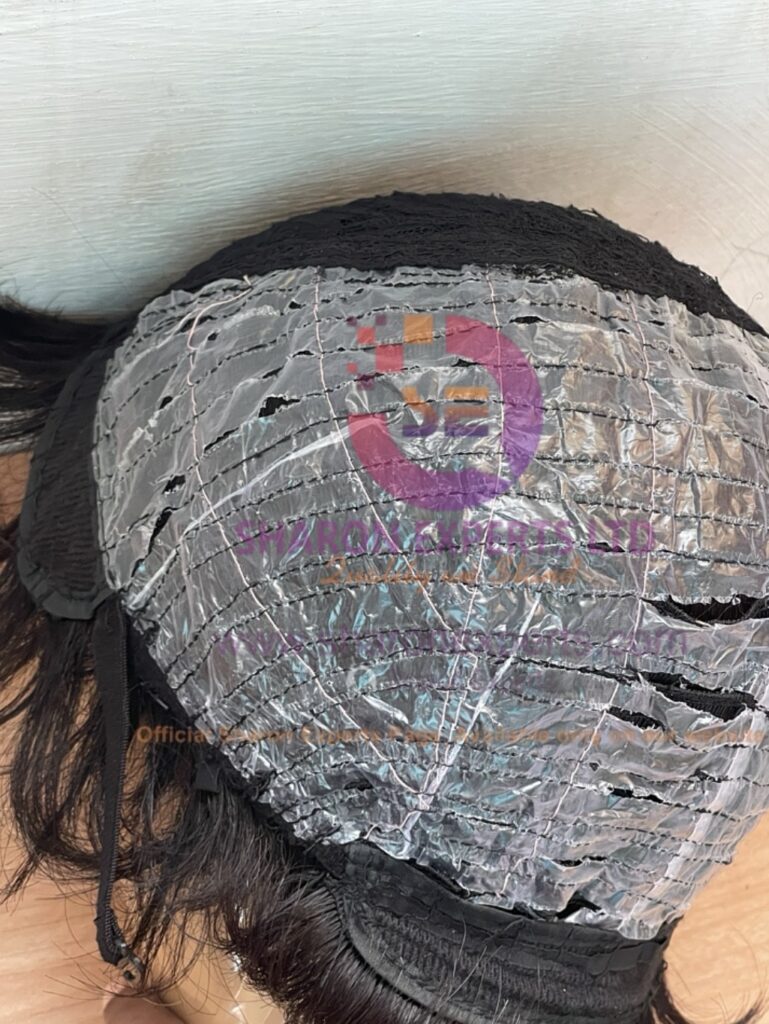

This view shows the internal cap structure during construction.

Each row is placed using controlled high-needle stitching to maintain balance, ventilation, and structural strength. The internal framework is built progressively to support the final shape and ensure the wig sits correctly when worn.

These images reflect actual in-progress work and demonstrate the care applied before finishing and styling.

At this stage, the cap foundation is fully aligned and reinforced.

Row spacing and tension are managed manually to prevent uneven density, excess bulk, or early loosening. This disciplined construction method comes from professional production practice where consistency is essential.

Custom Wig Construction (Measured Fit)

We provide wigs constructed according to individual head measurements rather than general sizing.

Each custom unit is built to match the client’s proportions for improved stability, comfort, and natural appearance. This service is suited for clients who want precision fit and carefully structured construction.

Mass Wigging Services

We also offer batch wig construction for businesses, brands, and resellers who require dependable workmanship.

Services include:

• Medium to large batch production

• Standard sizing or specified measurements

• Consistent construction across multiple units

• Reliable turnaround based on agreed timelines

This allows businesses to access professional-level production without managing manufacturing directly.

Client-Supplied Hair Construction

Clients and hair vendors may supply their own hair for professional wig construction.

We accept:

• Raw bundles

• Processed hair

• Vendor-supplied materials

• Client-sourced hair

Our role is to transform the supplied materials into a properly structured wig using disciplined construction methods.

All materials are reviewed before production begins to ensure suitability.

Who We Work With

We serve:

• Individual clients seeking custom wigs

• Hair vendors needing construction services

• Brands requiring batch production

• Stylists who want professionally built units

• Clients who value durability and proper structure

Our Approach

We believe the quality of a wig is determined by how it is built, not how it is advertised.

Our focus remains on disciplined workmanship, correct structure, and results clients can rely on repeatedly.

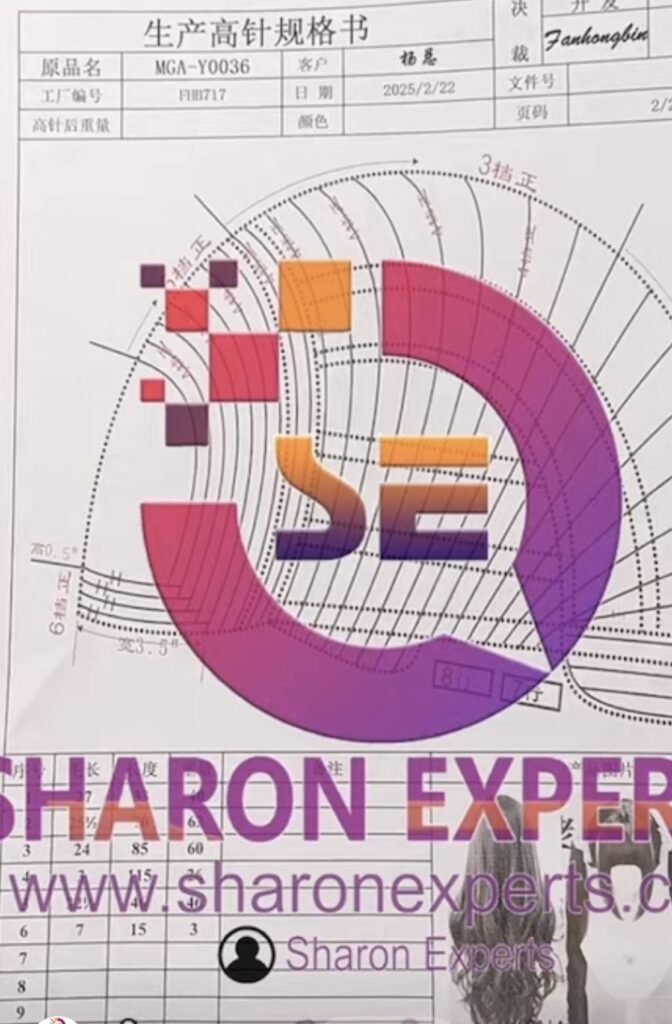

In professional wig making the base operation start with reading the wig structure not drawing guidelines

click on the image below to watch the video

Professional breakdown of the different caps used in wig construction.

Detailed Guide: Mesh Caps vs. Ventilated Caps

Choosing the right foundation is the most important step in wig construction. Here is a detailed look at the differences between the caps shown in this video below click on the pictures to watch :

Which Cap Should You Choose for Your Custom Wig?

As a professional factory wig maker, we use only high quality foundations for my construction. Here are the three professional options available for your unit:

1. Professional Mesh Cap

• The Fit: Very strong and holds its shape perfectly. It will not stretch out or get baggy over time.

• The Security: Provides a firm, snug feel. This is the best option for a secure, glueless fit.

• Durability: Built for heavy daily wear and frequent styling.

2. Ventilated Mesh Cap

• The Airflow: Designed with a special open net that lets your scalp breathe. This is a game changer for staying cool.

• The Feel: Makes the wig feel much lighter on your head all day.

• Scalp Health: Helps prevent heat buildup, keeping your natural hair healthy underneath.

3. Hybrid Ventilated Cap (Mesh Sides)

• The Design: This cap has a breathable net in the middle and strong mesh on both sides.

• The Best of Both: You get the cool airflow on your scalp, but the strong mesh sides give you extra stretch and a better grip around your ears.

• The Fit: Perfect for someone who wants to stay cool but needs that extra “snug” factory fit on the sides.

Quick Guide:

• Choose Mesh for a strong, snug fit that stays firm.

• Choose Ventilated to stay cool and feel lightweight.

• Choose Hybrid (Mesh Sides) for a breathable feel with extra security on the sides.